This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

CUSTOMER

Anthem Biosciences Private Limited

PROJECT CATEGORY

Pharmaceutical and Biosciences Industry

COMPLETED

2023-06-23T00:00:00

PROJECT BUDGET

>3Cr.

PROJECT DESCRIPTION

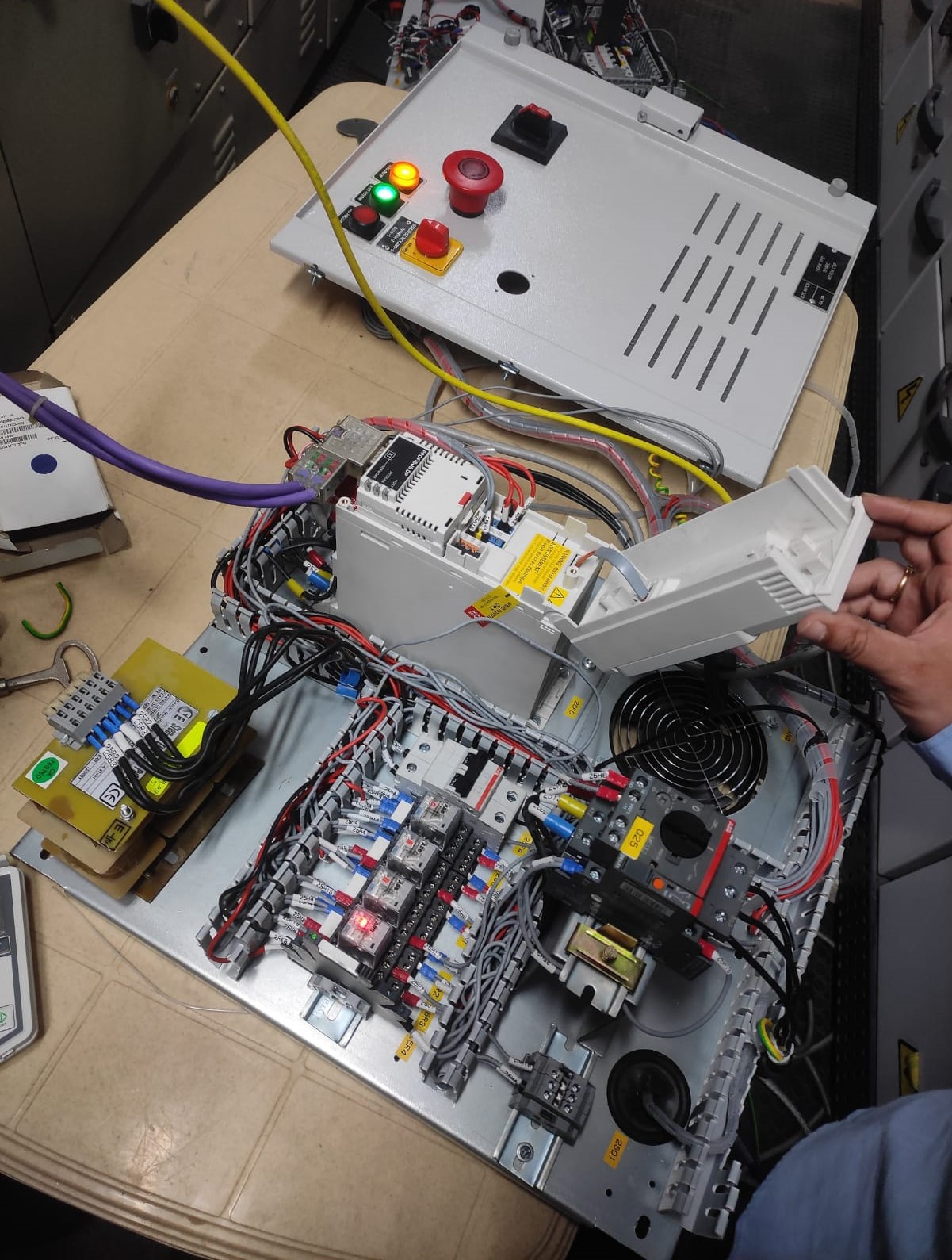

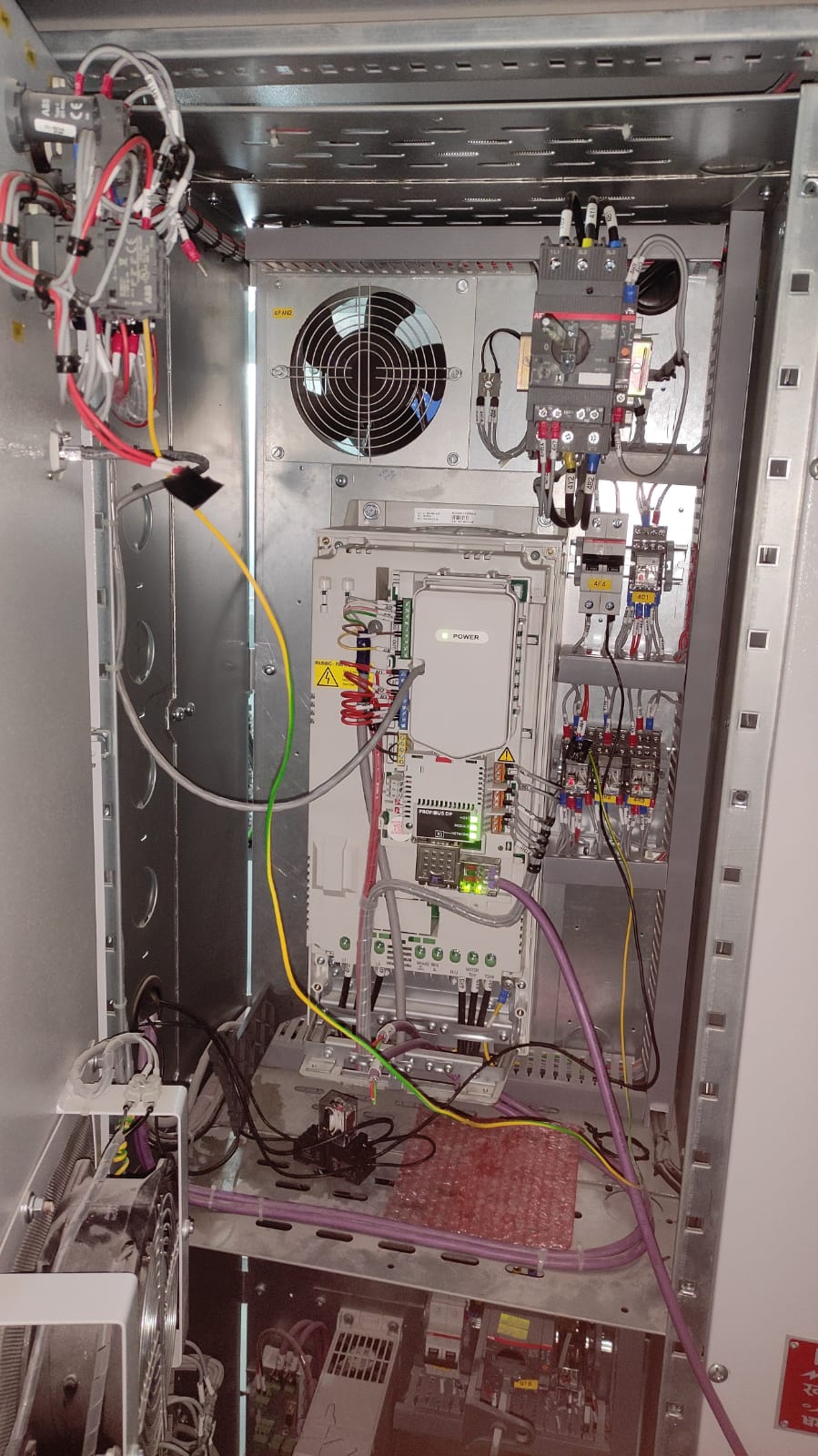

This project involved the supply, installation, programming, and commissioning of Variable Frequency Drives (VFDs) to meet the critical HVAC and process application requirements at Anthem Biosciences Private Limited. The project spanned one year, focusing on delivering a robust and efficient control solution tailored to the client's specifications.

CUSTOMER REQUIREMENT

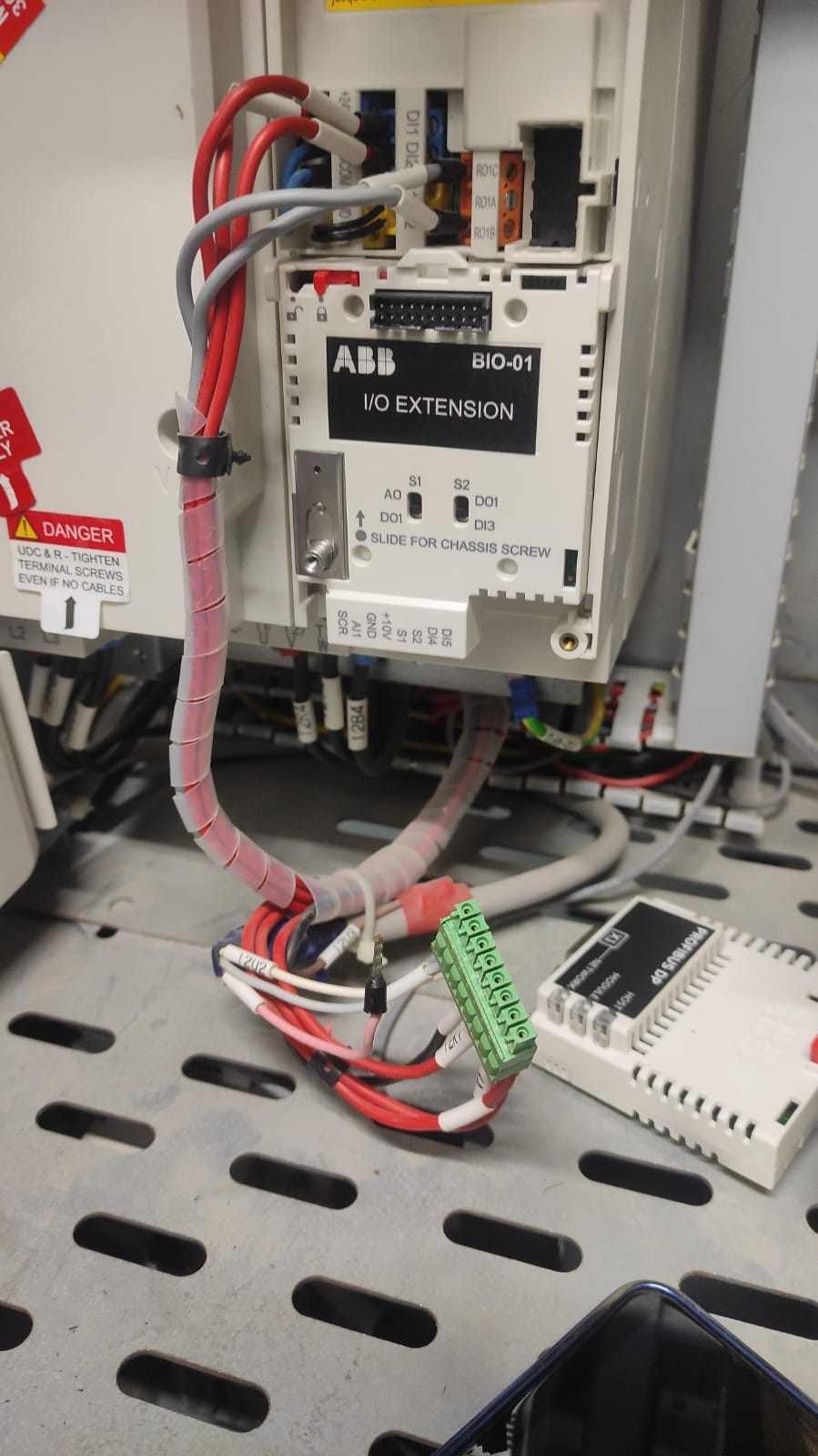

Anthem Biosciences required over 400 VFDs ranging from 0.75 kW to 315 kW for their HVAC and process applications. Their specific requirements included: • Operation of VFDs in two modes: Manual and Auto. • Manual control via panel door controls. • Auto control and monitoring through Profibus communication protocol. • An additional local control station (LCS) with start and emergency stop push buttons near the application.

WHAT WE DID

1. Product Supply: o Supplied ACS560 VFDs for capacities up to 160 kW. o Supplied ACS580 VFDs for capacities above 160 kW. 2. Programming and Commissioning: o Developed and implemented programming to meet dual-mode operational requirements (Manual and Auto). o Configured Profibus communication for Auto mode control and monitoring. o Designed and installed local control stations with push buttons for added flexibility. 3. Support and Training: o Conducted trials and adjustments to meet the desired operational parameters. o Delivered on-site training for site personnel, covering: Program changes and fault identification. Operational guidelines and troubleshooting instructions.

RESULT

The project was successfully completed, achieving all client requirements. Key results include: • All VFDs and control units are functioning as intended. • Smooth operation in both Manual and Auto modes. • Enhanced control and monitoring through Profibus protocol. • Improved operational efficiency for HVAC and process applications. • Empowered site personnel with the knowledge to manage and maintain the system effectively.

CUSTOMER

Anthem Biosciences Private Limited

PROJECT CATEGORY

Pharmaceutical and Biosciences Industry

COMPLETED

2023-06-23T00:00:00

PROJECT BUDGET

>3Cr.

PROJECT DESCRIPTION

This project involved the supply, installation, programming, and commissioning of Variable Frequency Drives (VFDs) to meet the critical HVAC and process application requirements at Anthem Biosciences Private Limited. The project spanned one year, focusing on delivering a robust and efficient control solution tailored to the client's specifications.

CUSTOMER REQUIREMENT

Anthem Biosciences required over 400 VFDs ranging from 0.75 kW to 315 kW for their HVAC and process applications. Their specific requirements included: • Operation of VFDs in two modes: Manual and Auto. • Manual control via panel door controls. • Auto control and monitoring through Profibus communication protocol. • An additional local control station (LCS) with start and emergency stop push buttons near the application.

WHAT WE DID

1. Product Supply: o Supplied ACS560 VFDs for capacities up to 160 kW. o Supplied ACS580 VFDs for capacities above 160 kW. 2. Programming and Commissioning: o Developed and implemented programming to meet dual-mode operational requirements (Manual and Auto). o Configured Profibus communication for Auto mode control and monitoring. o Designed and installed local control stations with push buttons for added flexibility. 3. Support and Training: o Conducted trials and adjustments to meet the desired operational parameters. o Delivered on-site training for site personnel, covering: Program changes and fault identification. Operational guidelines and troubleshooting instructions.

RESULT

The project was successfully completed, achieving all client requirements. Key results include: • All VFDs and control units are functioning as intended. • Smooth operation in both Manual and Auto modes. • Enhanced control and monitoring through Profibus protocol. • Improved operational efficiency for HVAC and process applications. • Empowered site personnel with the knowledge to manage and maintain the system effectively.